Donut Robots

Filters

- Belshaw Fryer (1)

- Belshaw Oil Filter (1)

- Cake Dropper Accessories (2)

- Counter Top Fryer (1)

- Donut Production Tables (5)

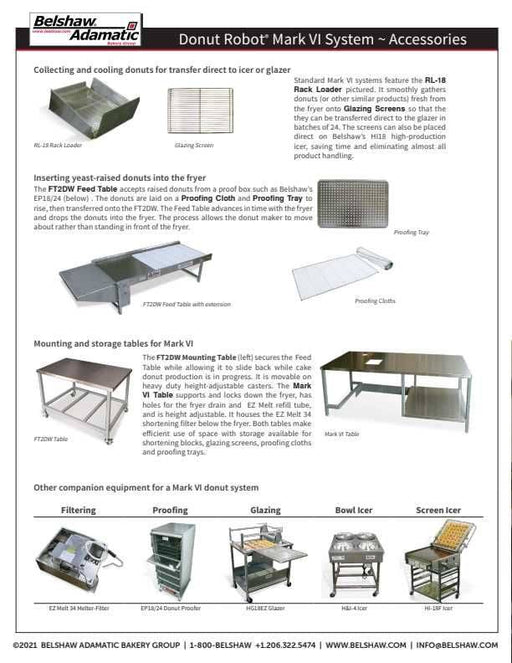

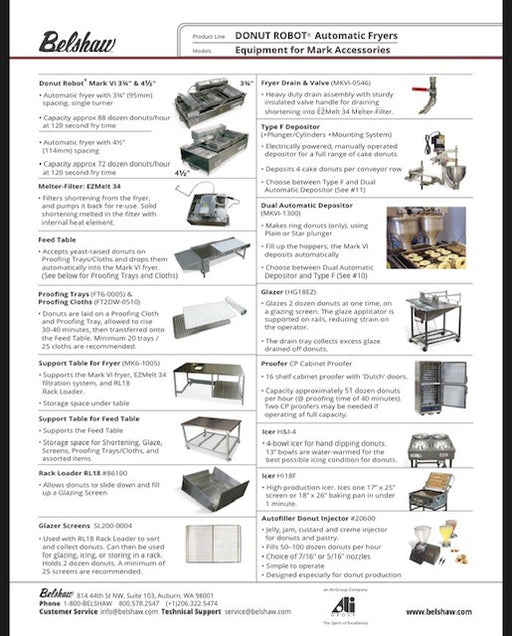

- Donut Robot Accessories (27)

- Donut Robot Hoppers (3)

- Donut Robot Plungers (6)

- Donut Robot Raised Dough Accessories (7)

- Donut Robots (29)

- Free Shipping (50)

- Full & Mini (2)

- Hopper for Depositor (2)

- Lil Orbits 1200 (3)

- Lil Orbits 2400 (2)

- Lil' Orbits (7)

- Mark ll Feed Table (1)

- Mark ll Proof Trays (1)

- Mark ll System (1)

- Mark ll/V Drain (2)

- Mark ll/V Proof Cloth (1)

- Mark V System (1)

- Mark Vl Drain Valve (1)

- Mark Vl Dual Depositor (1)

- Mark Vl Feed Table (3)

- Mark Vl Fryer Support Table (1)

- Mark Vl proofing tray (1)

- Mark Vl Rack Loader (1)

- Mark Vl Standard (3)

- mini donut cutter (2)

- Mini Robot (3)

- Proof Cloths For Vl (1)

- Rack Loader for Mark ll/V System (1)

- Shortening Filters (2)

- Shortening Reserve Tanks (1)

- Siphon Filter (1)

- Standard Robot (7)

- Ventless Donut Systems (10)

Save 6%

Save %

BELSHAW INSIDER Ventless Donut System -(APPROX- 226 DOZEN/HR) Mark V GP 208/240/60Hz/1 Ph

Save 6%

Save %

BELSHAW INSIDER Ventless Donut System -(APPROX- 226 DOZEN/HR) Mark V GP 208/240/60Hz/1 Ph

BELSHAW INSIDER Ventless Donut System -(APPROX- 226 DOZEN/HR) Mark V GP 208/240/60Hz/1 Ph

Belshaw AdamaticINSIDER Ventless Donut Center - Quality donuts in a fully certified mobile donut kiosk from Belshaw on Vimeo. BELSHAW INSIDER Ventless Donut Syste...

View full detailsBELSHAW INSIDER Ventless Donut System

Belshaw AdamaticINSIDER Ventless Donut Center - Quality donuts in a fully certified mobile donut kiosk from Belshaw on Vimeo. BELSHAW INSIDER Ventless Donut Syst...

View full details

Save 7%

Save %

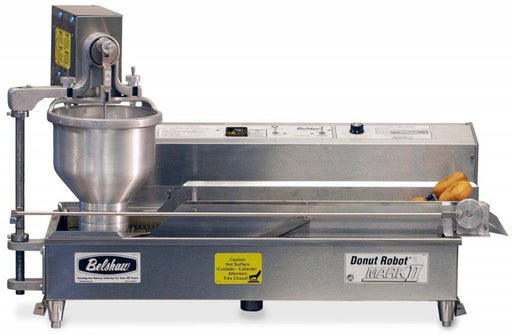

Belshaw Donut Robot® Mark VI (3-3/4" Flight Bar) with Dual Plain Depositor 1-9/16" for Cake Donut Production

Save 7%

Save %

Belshaw Donut Robot® Mark VI (3-3/4" Flight Bar) with Dual Plain Depositor 1-9/16" for Cake Donut Production

Belshaw Donut Robot® Mark VI (3-3/4" Flight Bar) with Dual Plain Depositor 1-9/16" for Cake Donut Production

Belshaw Adamatic(This listing is for the Mark Vl fryer sold with the 1-9/16" dual depositor) They can also be purchased separately. ▪Production capacity -Mark VI ...

View full details

Belshaw Donut Robot® Mark VI (4-1/2" Flight Bar) with Dual Plain Depositor 1-13/16" for Cake Donut Production

Belshaw Donut Robot® Mark VI (4-1/2" Flight Bar) with Dual Plain Depositor 1-13/16" for Cake Donut Production

Belshaw Donut Robot® Mark VI (4-1/2" Flight Bar) with Dual Plain Depositor 1-13/16" for Cake Donut Production

Belshaw Adamatic(This listing is for the Mark Vl fryer sold with the 1-13/16" dual depositor) They can also be purchased separately. ▪Production capacity -Mark VI...

View full detailsBelshaw Donut Robot® Mark VI Standard (4 variables in Variants)

Belshaw AdamaticBelshaw Donut Robot Mark VI system - for cake and yeast raised donuts from Belshaw on Vimeo. Belshaw Donut Robot® Mark VI Standard (3 variables i...

View full details

Save 7%

Save %

Belshaw Donut Robot® Mark II GP (Gas) Propane or Natural Gas for Mini Donuts only

Save 7%

Save %

Belshaw Donut Robot® Mark II GP (Gas) Propane or Natural Gas for Mini Donuts only

Belshaw Donut Robot® Mark II GP (Gas) Propane or Natural Gas for Mini Donuts only

Belshaw AdamaticBelshaw Donut Robot Mark II system - for cake donuts, yeast raised donuts, and mini donuts from Belshaw on Vimeo. Belshaw Donut Robot® Mark II GP ...

View full detailsBelshaw Donut Robot® Mark V (Electric) GP for Mini Donuts Only

Belshaw AdamaticAUTOMATED MINI DONUT MAKER, CAPACITY 151 DOZEN/HOUR, ELECTRIC. With the automated Belshaw donut robot mark V, you can simplify the donut frying pr...

View full detailsBelshaw Donut Robot® Mark II (Natural Gas or Propane) (3 variations available in Variants) Standard Donuts with Mini Donut Option

Belshaw AdamaticBelshaw Donut Robot Mark II system - for cake donuts, yeast raised donuts, and mini donuts from Belshaw on Vimeo. Belshaw Donut Robot® Mark II (Na...

View full details

Save 7%

Save %

Vendor Cart with Downdraft Filtration and Automatic Fire Suppression system (SS2400)

Save 7%

Save %

Vendor Cart with Downdraft Filtration and Automatic Fire Suppression system (SS2400)

Vendor Cart with Downdraft Filtration and Automatic Fire Suppression system (SS2400)

LIl OrbitsA Sophisticated Indoor Option Now you can operate the SS1200 or SS2400 donut machine in the open without hoods or ventilation! The Downdraft Syste...

View full detailsAFS24 "New" Advanced Filtration Cart for the SS2400 fryer

LIl OrbitsAFS-Series Advanced Filtration Carts- not be used with gas models For Odor-Free Cooking! Now you can operate the SS2400 donut machine in the open...

View full details

Save 7%

Save %

Belshaw Donut Robot® Mark V-Electric (2 Variables in Variants) With Mini Donut Option Available

Save 7%

Save %

Belshaw Donut Robot® Mark V-Electric (2 Variables in Variants) With Mini Donut Option Available

Belshaw Donut Robot® Mark V-Electric (2 Variables in Variants) With Mini Donut Option Available

Belshaw AdamaticAUTOMATED DONUT MAKER FOR STANDARD SIZE DONUTS. CAPACITY 56 DOZEN/HOUR, ELECTRIC. With the automated Belshaw donut robot mark V, you can simplify...

View full details

Save 7%

Save %

Vendor Cart with Downdraft Filtration and Automatic Fire Suppression System (SS1200)

Save 7%

Save %

Vendor Cart with Downdraft Filtration and Automatic Fire Suppression System (SS1200)

Vendor Cart with Downdraft Filtration and Automatic Fire Suppression System (SS1200)

LIl OrbitsA Sophisticated Indoor Option Now you can operate the SS1200 or SS2400 donut machine in the open without hoods or ventilation! The Downdraft Syst...

View full details

Save 7%

Save %

Belshaw Donut Robot® Mark II GP Electric Mini Donut Maker Only (3 Options in Variants)

Save 7%

Save %

Belshaw Donut Robot® Mark II GP Electric Mini Donut Maker Only (3 Options in Variants)

Belshaw Donut Robot® Mark II GP Electric Mini Donut Maker Only (3 Options in Variants)

Belshaw AdamaticBelshaw Donut Robot Mark II system - for cake donuts, yeast raised donuts, and mini donuts from Belshaw on Vimeo. Belshaw Donut Robot® Mark II GP ...

View full details

Save 7%

Save %

Belshaw Donut Robot® Mark II (4 Variations in variants) Standard Donut /Mini Option Available

Save 7%

Save %

Belshaw Donut Robot® Mark II (4 Variations in variants) Standard Donut /Mini Option Available

Belshaw Donut Robot® Mark II (4 Variations in variants) Standard Donut /Mini Option Available

Belshaw AdamaticBelshaw Donut Robot Mark II system - for cake donuts, yeast raised donuts, and mini donuts from Belshaw on Vimeo. Belshaw Donut Robot® Mark II (6 ...

View full detailsAFS12 "New" Advanced Filtration Cart for the SS1200 fryer

LIl Orbits* Not to be used with gas models AFS-Series Advanced Filtration Carts For Odor-Free Cooking! Now you can operate the SS1200 or SS2400 donut machi...

View full details

Save 7%

Save %

Lil Orbits Ventless Hood 1200 Producer Package with SS1200 Donut Machine

Save 7%

Save %

Lil Orbits Ventless Hood 1200 Producer Package with SS1200 Donut Machine

Lil Orbits Ventless Hood 1200 Producer Package with SS1200 Donut Machine

LIl OrbitsHere's a money-maker for any high traffic location! Power through your events with confidence using this premium package featuring the SS1200 donut...

View full details

Save 7%

Save %

Dual Automatic Depositor Kit for Mark VI and Mark VI (Deep) (5 options in Variants available)

Save 7%

Save %

Dual Automatic Depositor Kit for Mark VI and Mark VI (Deep) (5 options in Variants available)

Dual Automatic Depositor Kit for Mark VI and Mark VI (Deep) (5 options in Variants available)

Belshaw AdamaticDescription: The Dual Depositor Kit can be installed on the Mark VI fryer (or Mark VI 'Deep' fryer) at the time of manufacture or can be retrofitte...

View full details

Save 7%

Save %

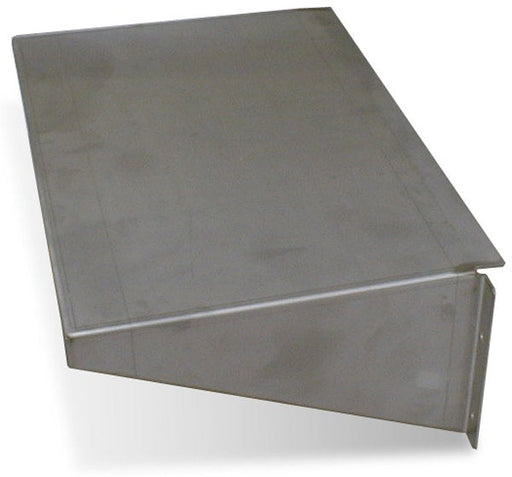

Belshaw Feed Table for Mark VI with 12 Inch Extension for Yeast Raised Donuts

Save 7%

Save %

Belshaw Feed Table for Mark VI with 12 Inch Extension for Yeast Raised Donuts

Belshaw Feed Table for Mark VI with 12 Inch Extension for Yeast Raised Donuts

Belshaw AdamaticBelshaw Donut Robot Mark VI system - for cake and yeast raised donuts from Belshaw on Vimeo. VI Feed Table 12 Inch Extension Belshaw Feed Tabl...

View full detailsModel FSC-10 (without downdraft filtration) FSC-Series Vendor Carts

LIl OrbitsA Sophisticated Indoor Option Now you can operate the SS1200 or SS2400 donut machine in the open without hoods or ventilation! The Downdraft Syst...

View full details

Save 7%

Save %

Belshaw Feed Table for Mark VI Deep (extra Height) for Yeast Raised Donuts

Save 7%

Save %

Belshaw Feed Table for Mark VI Deep (extra Height) for Yeast Raised Donuts

Belshaw Feed Table for Mark VI Deep (extra Height) for Yeast Raised Donuts

Belshaw AdamaticBelshaw Feed Table for Mark VI Deep for Yeast Raised Donuts This 4 donut wide feed table is a must for your donut operation on a Donut Robot Mark ...

View full detailsBelshaw Support table for Mark VI Fryer (MK6-1005)

Belshaw AdamaticSupport Table for the Mark VI (MK6-1005) Designed to withstand the weight of the fryer and the weight of the cooking oil. Don't allow yourself to...

View full detailsBelshaw Donut Robot Table Mark II, Mark V, and Mark VI Support Table

Belshaw AdamaticBelshaw Donut Robot Table Mark II, Mark V, and Mark VI Support Table The Support Table is designed to safely support all Donut Robot® fryers, Roto-...

View full detailsBelshaw FT42 Feed Table for Mark ll or Mark V Yeast Raised Donuts

Belshaw AdamaticBelshaw FT42 Feed Table for Mark ll or Mark V Yeast Raised Donuts For FT42 Feed Table This unit has space for 2 donuts wide it's an essential part ...

View full detailsLil Orbits Ventless Hood 1200 Producer Package(No Donut Machine)

LIl OrbitsHere's a money-maker for any high traffic location! This complete startup solution eliminates the complexity of launching a donut operation at temp...

View full details