Donut Sheeters

With a compact simple design, even the most inexperienced employees can sheet dough in seconds. With adding different attachments available for cutting, donuts, croissants, turnovers, and other pastries becomes automatic and uniform.

Donut Dough is a dense heavy dough compared to many of the pastry doughs. The machines listed below make quick work of sheeting and also cutting dough for donuts.

Filters

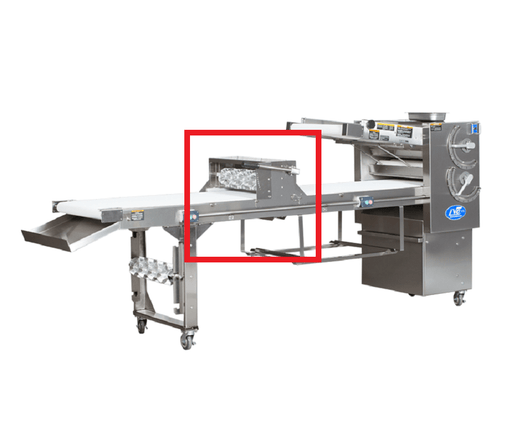

LVO SM224-6 Donut Production Table Sheeter Right To Left Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Right to Left production indicates that you are standing at the front (wher...

View full detailsLVO SM224-6 Donut Production Table Sheeter Left To Right Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Left to Right production indicates that you are standing at the front (wher...

View full details

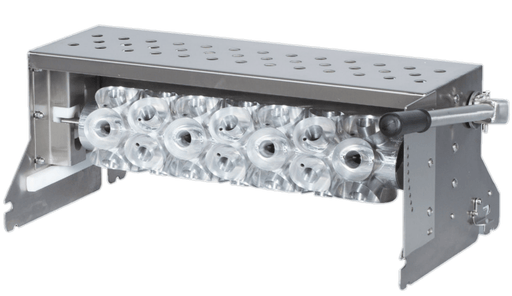

SM224 Removable Cutter Carriage

SM224 Removable Cutter Carriage

SM224 Removable Cutter Carriage

LVOAlready have a LVO SM224 Dough Sheeter but don't have the cutter attachment. The Cutter carriage is designed to work with all LVO SM224 series, 6,9...

View full detailsLVO SM224-9 Donut Production Table Sheeter Right to Left Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Right to Left production indicates that you are standing at the front (wher...

View full detailsLVO SM224-9 Donut Production Table Sheeter Left to Right Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Left to Right production indicates that you are standing at the front (wher...

View full detailsACME 330DD Donut Production Sheeter (120V) Left To Right Production 96"

Acme* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Left to Right production indicates that you are standing at the front (wher...

View full detailsACME 330DD Standard Donut Production Sheeter (200-240V) Left To Right Production

AcmeThe Model 330DD Donut Production Table only requires 96" floor space. This space saving design provides many options for operator floor plan design...

View full detailsACME 330DD Donut Production Sheeter (120V) Right To Left Production 96"

Acme* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Left to Right production indicates that you are standing at the front (wher...

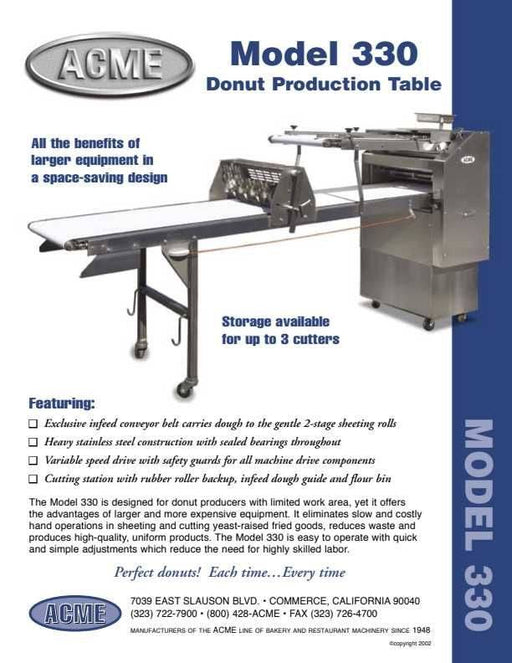

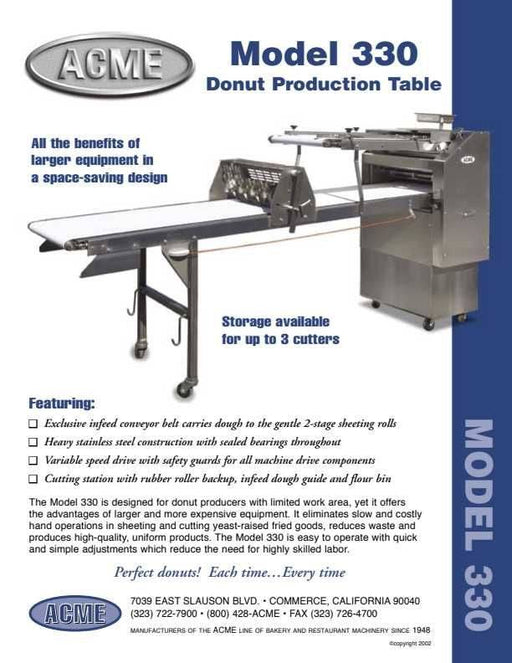

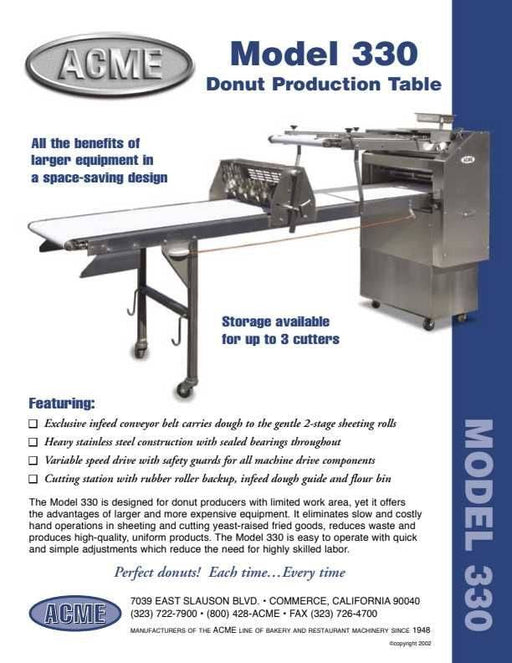

View full detailsACME 330 Standard Donut Production Sheeter (120V) Left To Right Production

AcmeThe Model 330 Donut Production Table only requires 72" floor space. This space saving design provides many options for operator floor plan design. ...

View full detailsACME 330 Standard Donut Production Sheeter (200-240V) Left To Right Production

AcmeThe Model 330 Donut Production Table only requires 72" floor space. This space saving design provides many options for operator floor plan design. ...

View full detailsACME 330 Standard Donut Production Sheeter (120V) Right To Left Production

AcmeThe Model 330 Donut Production Table only requires 72" floor space. This space saving design provides many options for operator floor plan design. ...

View full detailsACME 330 Standard Donut Production Sheeter (200-240V) Right To Left Production

AcmeThe Model 330 Donut Production Table only requires 72" floor space. This space saving design provides many options for operator floor plan design. ...

View full details

Somerset CDR-500 - Dough Roller Sheeter - 20" Single Pass- Recommended for Donut Dough

Somerset CDR-500 - Dough Roller Sheeter - 20" Single Pass- Recommended for Donut Dough

Somerset CDR-500 - Dough Roller Sheeter - 20" Single Pass- Recommended for Donut Dough

Somerset IndustriesIf you're in the market for a quick and efficient way to create pie crusts, pizza, pasta, and other dough of uniform thickness, consider this singl...

View full detailsACME 330DD Standard Donut Production Sheeter (200-240V) Right to Left Production

AcmeThe Model 330DD Donut Production Table only requires 96" floor space. This space saving design provides many options for operator floor plan design...

View full details