Tables

Filters

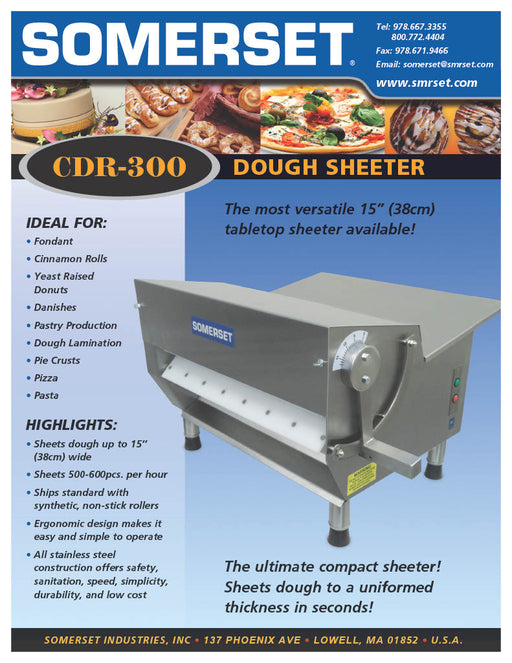

- Counter Top Sheeter (1)

- Donut Finishing Table (7)

- Donut Production Tables (8)

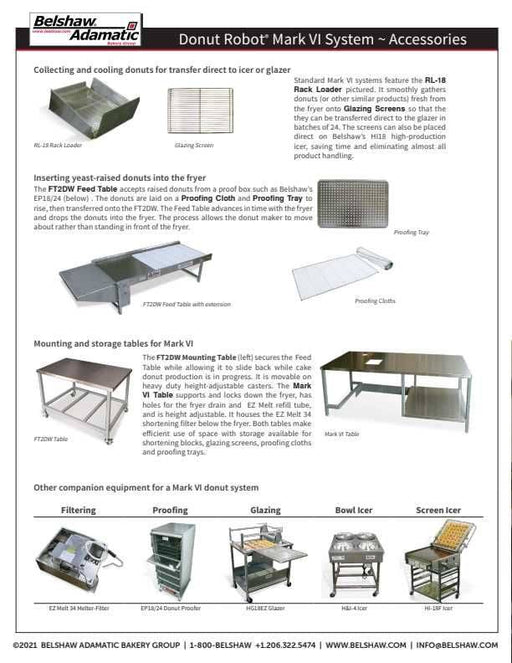

- Donut Robot Accessories (11)

- Donut Robot Raised Dough Accessories (5)

- Donut Robots (12)

- Dough Sheeter (1)

- Floor Model Sheeter (4)

- Free Shipping (36)

- Galvanized Legs (2)

- Glazer (3)

- Icing/Glazing table (2)

- Icing/Glazing Tables (2)

- LVO Sheeter (4)

- Mark ll Feed Table (1)

- Mark ll Proof Trays (1)

- Mark ll/V Drain (1)

- Mark Vl Drain Valve (1)

- Mark Vl Feed Table (3)

- Mark Vl Fryer Support Table (1)

- Mark Vl proofing tray (1)

- Mark Vl Standard (2)

- Single Overshelf Table Mounts (2)

- Stainless Steel Legs (4)

- Standard Robot (2)

- Sugaring Table (7)

Save 7%

Save %

Avalon (AIGT-26) 18" x 26" Compatible Icing/Glazing Prep Table (Not Heated)

Save 7%

Save %

Avalon (AIGT-26) 18" x 26" Compatible Icing/Glazing Prep Table (Not Heated)

Avalon (AIGT-26) 18" x 26" Compatible Icing/Glazing Prep Table (Not Heated)

AvalonAvalon AIGT-24 Icing/Glazing Prep Table 24" x 24" compatible (non-heated) The Combination Icing/Glazing Tables are designed to make all your glazi...

View full detailsAvalon (HI24G26) "24 x24" Heated Icing with an 18" x 26" compatible Glazer (Not Heated), built into a Stainless Prep Table

AvalonUpgrade your donut production with the Avalon HI24G26, a heated combination icing/glazing table built into a sturdy stainless steel prep table. Don...

View full detailsBK Double Overshelf Table Mount 12" X 96", 18 GA. SS

BK ResourcesThis BK Resources product is a 96"W x 12"D 18G Stainless Steel Table-Mount Double Over shelf, Double Over shelf, table mount, 96"W x 12"D x 31-1/4"...

View full detailsBelshaw Support table for Mark VI Fryer (MK6-1005)

Belshaw AdamaticSupport Table for the Mark VI (MK6-1005) Designed to withstand the weight of the fryer and the weight of the cooking oil. Don't allow yourself to...

View full detailsAvalon Donut Finishing / Sugaring Table AFT-48-2-1

AvalonAvalon Donut Finishing / Sugaring Table AFT-48-2-1 Avalon Donut Finishing / Sugaring Table is a perfect addition to your kitchen. All stainless-ste...

View full detailsAvalon Donut Finishing / Sugaring Table AFT-60-2-1

AvalonAvalon Donut Finishing / Sugaring Table AFT-60-2-1 Avalon Donut Finishing / Sugaring Table is a perfect addition to your kitchen. All stainless-ste...

View full detailsAvalon Donut Finishing / Sugaring Table AFT-96-4-2

AvalonAvalon Donut Finishing / Sugaring Table AFT-96-4-2 Avalon Donut Finishing / Sugaring Table is a perfect addition to your kitchen. All stainless-ste...

View full detailsTable Top Automatic Sugar Tumbler w/ automatic Conveyor for Belshaw Mark Vl Fryer

Belshaw AdamaticDescription This Sugar Tumbler is the best method for midsize and large donut producers to apply sugar or cinnamon sugar coatings to donuts of any ...

View full details Manual Sugar Tumbler tabletop w/ drum and Chute assembly

Manual Sugar Tumbler tabletop w/ drum and Chute assembly

Manual Sugar Tumbler tabletop w/ drum and Chute assembly

Belshaw AdamaticDescription This manual sugar tumbler creates speed and efficiency. A stainless steel drumtumbler spins the sugar and the donuts while the spiral r...

View full details

Save 9%

Save %

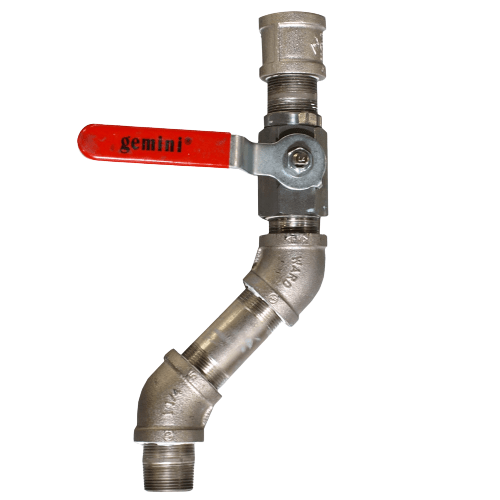

Belshaw Donut Robot Mark II, Mark V, and Mark VI Fryer Drain Valve for Support Table (2 Variables in Variants)

Save 9%

Save %

Belshaw Donut Robot Mark II, Mark V, and Mark VI Fryer Drain Valve for Support Table (2 Variables in Variants)

Belshaw Donut Robot Mark II, Mark V, and Mark VI Fryer Drain Valve for Support Table (2 Variables in Variants)

Belshaw Adamatic2 options available in Variants for the; Mark II or the Mark V/ Mark VI Belshaw Fryer Drain Valve f...

View full details72" X 30" T-430 18 GA Table Stainless Steel Top, Shelf and Legs

BK ResourcesWork Table, 72"W x 30"D, 18/430 stainless steel top, with turndown edges on front & sides, reinforced with channels, 1-1/2" rear riser, adjusta...

View full details Save 17%

Save %

60" X 30" T-430 18 GA Table SS Top

Save 17%

Save %

60" X 30" T-430 18 GA Table SS Top

60" X 30" T-430 18 GA Table SS Top

BK ResourcesWork Table, 60"W x 30"D, 18/430 stainless steel top, with turndown edges on front & sides, reinforced with channels, 1-1/2" rear riser, adjusta...

View full details Save up to 28%

Save %

48" X 30" T-430 18 GA Table SS Top

Save up to 28%

Save %

48" X 30" T-430 18 GA Table SS Top

48" X 30" T-430 18 GA Table SS Top

BK ResourcesWork Table, 48"W x 30"D, 18/430 stainless steel top, with turndown edges on front & sides, reinforced with channels, 1-1/2" rear riser, adjusta...

View full details Save 13%

Save %

36" X 30" T-430 18 GA Table SS Top

Save 13%

Save %

36" X 30" T-430 18 GA Table SS Top

36" X 30" T-430 18 GA Table SS Top

BK ResourcesWork Table, 36"W x 30"D, 18/430 stainless steel top, with turn down edges on front & sides, reinforced with channels, 1-1/2" rear riser, adjust...

View full details Save 7%

Save %

96" X 30" T-430 18 GA Table SS Top

Save 7%

Save %

96" X 30" T-430 18 GA Table SS Top

96" X 30" T-430 18 GA Table SS Top

BK ResourcesWork Table, 96"W x 30"D, 18/430 stainless steel top, with turndown edges on front & sides, reinforced with channels, 1-1/2" rear riser, adjusta...

View full details Save up to 20%

Save %

84" X 30" T-430 18 GA Table SS

Save up to 20%

Save %

84" X 30" T-430 18 GA Table SS

84" X 30" T-430 18 GA Table SS

BK ResourcesWork Table, 84"W x 30"D, 18/430 stainless steel top, with turndown edges on front & sides, reinforced with channels, 1-1/2" rear riser, adjusta...

View full details Save 7%

Save %

BK Resources BK-OSS-1296 Single Overshelf Table Mount 12 X 72, 18 GA. SS

Save 7%

Save %

BK Resources BK-OSS-1296 Single Overshelf Table Mount 12 X 72, 18 GA. SS

BK Resources BK-OSS-1296 Single Overshelf Table Mount 12 X 72, 18 GA. SS

BK ResourcesSingle Overshelf, table mount, 96"W x 12"D x 18"H, 18/304 stainless steel, self tapping screws, shipped KD BK Resources BK-OSS-1296

Save 7%

Save %

BK Resources BK-OSS-1272 Single Overshelf Table Mount 12 X 72, 18 GA. SS

Save 7%

Save %

BK Resources BK-OSS-1272 Single Overshelf Table Mount 12 X 72, 18 GA. SS

BK Resources BK-OSS-1272 Single Overshelf Table Mount 12 X 72, 18 GA. SS

BK ResourcesSingle Overshelf, table mount, 72"W x 12"D x 18"H, 18/304 stainless steel, self tapping screws, shipped

LVO SM224-9 Donut Production Table Sheeter Right to Left Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Right to Left production indicates that you are standing at the front (wher...

View full detailsLVO SM224-9 Donut Production Table Sheeter Left to Right Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Left to Right production indicates that you are standing at the front (wher...

View full detailsLVO SM224-6 Donut Production Table Sheeter Right To Left Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Right to Left production indicates that you are standing at the front (wher...

View full detailsLVO SM224-6 Donut Production Table Sheeter Left To Right Production

LVO* Includes Doughnut Cutter Assembly for the 26" Shaft Rotary Cutters- * Left to Right production indicates that you are standing at the front (wher...

View full detailsCDR-300 Dough Sheeter 15" wide Table-Top Sheeter

Somerset IndustriesThe ultimate compact sheeter! Sheets dough to a uniformed thickness in seconds! Sheets dough up to 15” (38cm) wide, Sheets 500-600pcs. per hour. Sh...

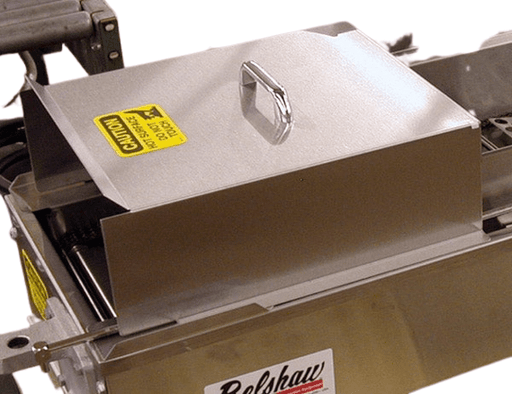

View full detailsBelshaw Splash guard for Mark ll / Mark V (used with Feed Table)

Belshaw AdamaticSplatter shield for Mark ll / Mark V fryer. Each shield is made of a sheet of stainless steel with a strip on the bottom for holding onto the Bel...

View full details