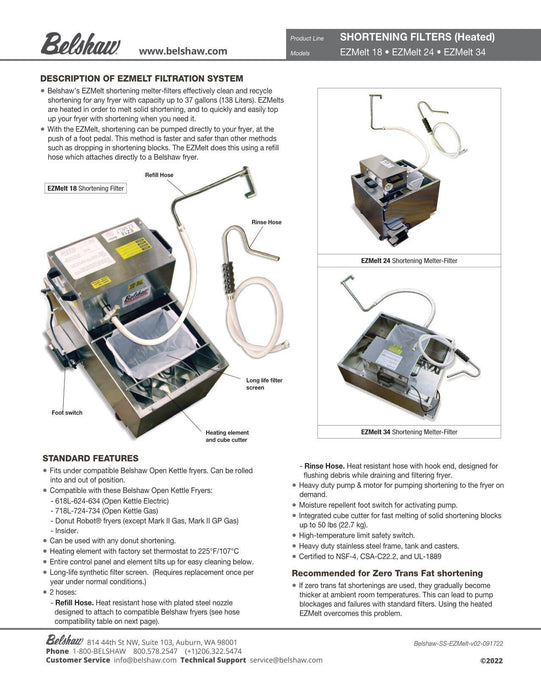

EZMelt 34 (includes rinse and fill hose)

THE BEST FILTRATION SYSTEM FOR 734CG, 734FG, MELTS, FILTERS AND PUMPS BACK ON DEMAND.

Compatible with 734CG and 734FG fryers, and Donut Robot ® Mark VI.

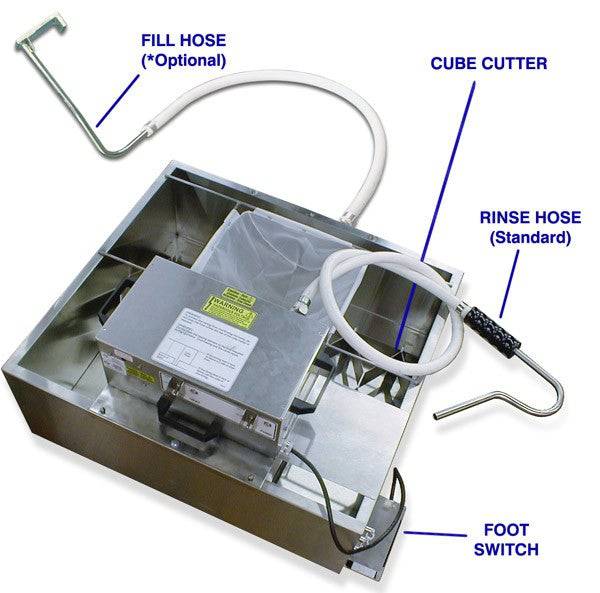

The EZMelt filtration system is the only filtration system recommended if you use Trans Fat-free shortening. The EZMelt34 is a recycling filter that heats shortening in the tank, with these benefits: If Zero Trans Fat shortenings are used, they gradually become thicker at normal bakery temperatures. This can lead to pump blockages and failures with standard filters. Using the heated EZ Melt overcomes this problem. Pumping reheated shortening through a fixed connection to the fryer is faster and safer than any other method, such as dropping in shortening blocks. The EZMelt does this using a refill hose (optional) which attaches directly to a Belshaw fryer.

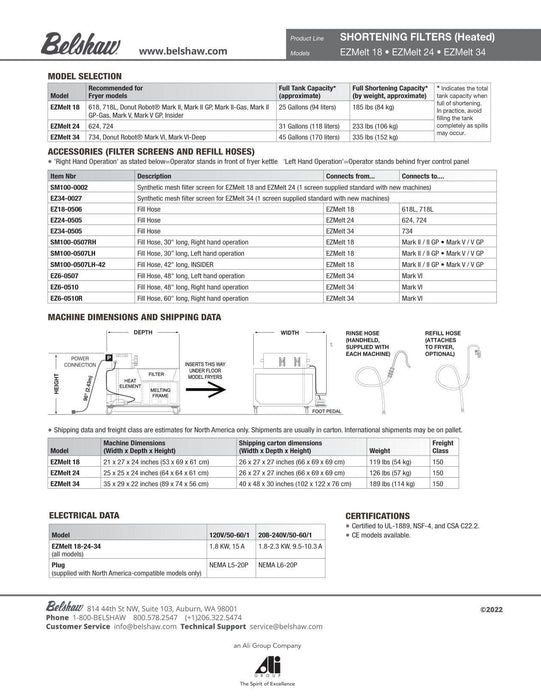

Standard features: Capacity 31.25 gallons (118 Liters), approximately equivalent to 225 lbs (102 kg) shortening.

Compatible with Belshaw's floor model 734LFG and 734LCG fryers, and with Donut Robot ® Mark VI. For other brand fryers, check capacity and dimensions to determine compatibility. Can be used with any standard donut shortening including Zero Trans Fat shortening. Heating element with factory set thermostat to 225°F/107°C.

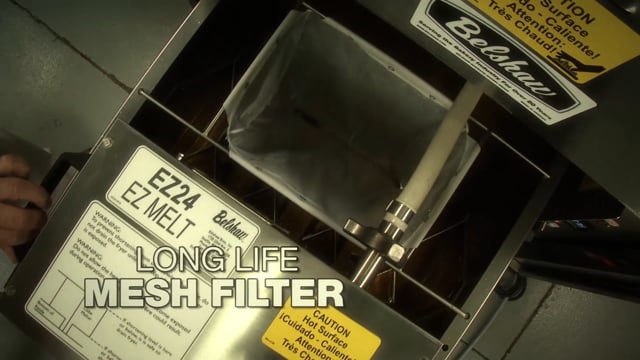

Element tilts up for easy tank cleaning. Tank itself is readily removable. Long-life synthetic filter screen that needs only annual replacement under normal operating conditions. Heavy duty pump & motor for pumping shortening to the fryer on demand. Heavy duty, moisture repellent foot switch for activating pump. Cube cutter for fast melting of solid shortening blocks up to 50lbs (22.7kg) Hand held rinse hose with heat resistant handle. Optional Refill Hose - allows regular topping up of fryer through a fixed connection to the fryer. The refill hose can be left in place on a Belshaw fryer at all times allowing frequent topping up of shortening level. High-temperature limit switch.

120V or 240V, 50 or 60 Hz, 1-Phase. Certified by ETL to NSF Std 4, CSA C22.2, and UL 1889.